As we grapple with climate change, finding eco-friendly alternatives for everyday items has become more than just a trend – it’s a necessity. One such item that’s been popping up (pun intended) in eco-friendly discussions is bubble wrap insulation. But is it really as green as it’s cracked up to be?

Understanding Bubble Wrap Insulation

In the quest for eco-friendly alternatives, bubble wrap insulation emerges as a compelling topic. To discern if it’s as sustainable as claimed, it’s worthwhile examining its history, production, and usage.

Brief History of Bubble Wrap

Engineers Alfred Fielding and Marc Chavannes invented Bubble Wrap in 1957, seeking to create a trendy wallpaper. When this venture flopped, they found ample success in positioning their invention as packing material. Its insulating properties, discovered later, paved the way for its use as eco-friendly insulation.

How Bubble Wrap Is Produced

Bubble wrap production begins with polyethylene resin, a type of plastic. This resin’s heated, melting into a thin film. High-pressure air’s then pushed into the film, forming bubbles. Although polyethylene’s not biodegradable, manufacturers recycle waste during production, affirming bubble wrap’s eco-friendly stance.

Common Uses of Bubble Wrap

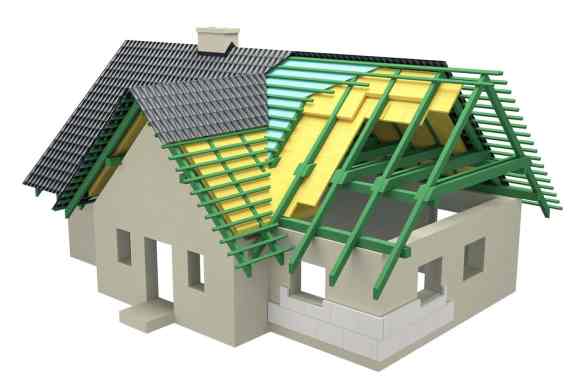

Besides packaging fragile items, bubble wrap excels in insulation within buildings. The bubbles trap heat, minimizing temperature fluctuations and energy usage, which ticks the boxes for eco-friendly insulation. Outdoor enthusiasts also use bubble wrap for insulating camping gear. It is especially favorable in DIY projects due to its affordability and ease-of-use.

Examining the Environmental Impact of Bubble Wrap

As one journeys deeper into the world of bubble wrap insulation, a thorough understanding of its environmental impact becomes crucial. In this section, we will break down this impact by examining the materials and manufacturing process, energy consumption, and waste management practices tied to bubble wrap.

Raw Materials and Manufacturing Process

In its crux, bubble wrap insulation primarily comprises polyethylene, a type of plastic that isn’t biodegradable. This leads to questions about its eco-friendliness. However, the manufacturing process looks to balance this concern.

Most polyethylene used is recyclable and manufacturers take measures to recycle waste generated during the manufacturing process. Emphasis on waste reduction and responsible utilization of raw materials contributes significantly to the sustainability of bubble wrap as an insulation material.

Energy Consumption

Bubble wrap scores relatively well in terms of energy consumption. The energy required to create polyethylene for bubble wrap is lesser when compared to other insulation materials. Moreover, bubble wrap reduces energy consumption in its use as insulation, trapping heat effectively in buildings and reducing the need for artificial heating. This aspect underscores its suitability as an eco-friendly insulation alternative.

Waste Management and Recycling

Waste generated through the life cycle of bubble wrap insulation remains a critical point of discussion. While the material is predominantly non-biodegradable, it is extensively recyclable. Manufacturers often repurpose the material from bubble wrap waste into other products, thereby reducing landfill disposal. Additionally, initiatives to reduce production waste in the manufacturing process enhance bubble wrap’s standing as a sustainable insulation option.

Sustainability of Bubble Wrap Insulation

I delve deep into the sustainability aspects of bubble wrap insulation. Assessing its lifespan, reusability, recycling, and carbon footprint provides insights into its eco-friendly potential.

Product Lifespan

Bubble wrap insulation flaunts considerable durability. A well-kept piece can last up to 7 years, saving resources that would’ve gone into producing and replacing less enduring materials. Its resilience to external stressors, like temperature fluctuations and humidity, further extends its lifespan. Understanding this, one sees bubble wrap insulation as an outlasting and reliable insulation choice.

Reusability and Recycling

The reusability and recycling of bubble wrap insulation underscore its sustainability. With creative thinking, one can repurpose used bubble wrap, diverting it from the waste stream. Additionally, bubble wrap, being predominantly made up of number 4 plastic or LDPE (Low-Density Polyethylene), is recyclable. The key is to provide it to recycling facilities that are equipped to handle this material, transforming it into products like trash bin liners and plastic lumber. Hence, activating circularity in its life cycle.

Carbon Footprint

The carbon footprint of a product is indicative of its environmental impact. From production to disposal, bubble wrap insulation accrues a lower carbon footprint compared to traditional insulation like fiberglass. Its energy-efficient manufacturing process, recycling potential, and effective heat retention capabilities significantly reduce CO2 emissions. Therefore, selecting bubble wrap insulation can be a step towards reducing the environmental footprint.

Eco-friendly Alternatives to Bubble Wrap Insulation

As we venture into a more sustainable world, the search for eco-friendly insulation alternatives has become paramount. Let’s delve into three potential alternatives that can compete with traditional bubble wrap insulation in terms of effectiveness and eco-friendliness.

Paper-Based Products

Rather surprisingly, paper has emerged as an eco-friendly insulation substitute. Leveraging its abundant availability and versatility, manufacturers now produce paper-based insulations that notably outperform traditional counterparts.

For example, cellulose insulation, predominantly made from recycled paper, proves to be an energy-efficient alternative. It traps air in buildings and resists heat flow due to its high R-value. Its recyclability and relatively low energy cost during production also solidify its position as an environmentally friendly insulation option.

Biodegradable Packing Materials

The advent of biodegradable packing materials provides an ecological alternative for insulation. Products such as StarchTech’s biodegradable peanuts and Ecoware’s packing materials facilitate thermoregulation, like traditional insulation, but drastically reduce the environmental impact. Both are crafted from renewable, often plant-based materials. These organic components decompose over time, reducing waste production, and their manufacturing processes curtail energy consumption compared to traditional insulation materials.

Innovative Eco-friendly Solutions

Innovation continues to push the boundaries in search of environment-friendly insulation solutions. Take Aerogel insulation, a synthetic porous ultralight material derived from a gel, whose liquid component has been replaced with a gas. With its high R-value per inch, it supersedes conventional insulation in effectively reducing energy consumption aptly demonstrating that it isn’t necessary to compromise insulation performance for sustainability.

Other innovative materials, like sheep’s wool and recycled denim, provide additional eco-friendly insulation opportunities. They incorporate reused or recycling components, reducing waste and carbon emissions, thus aligning with our sustainable goals.

Comparing Bubble Wrap Insulation and Eco-friendly Alternatives

This section focuses on the ins and outs of bubble wrap insulation and its eco-friendly counterparts, drawing attention to material and design, functional capabilities, environmental impacts, and cost effectiveness.

Material and Design

Bubble wrap insulation is crafted mainly from low-density polyethylene (LDPE), living up to its namesake with a unique design composed of multiple tiny air pockets. The LDPE composition allows bubble wrap to be fairly resistant to moisture, corrosion, impact and UV radiation.

In contrast, eco-friendly insulations, like cellulose or sheep’s wool, are comprised of either recycled or natural materials. A standout, Aerogel insulation, showcases innovation with its lightweight yet dense design crafted from silica. It’s these eco-conscious designs that push towards a sustainable future.

Functional Capabilities

There is no denying bubble wrap insulation’s ability to block radiant heat, significantly reducing energy consumption. Still, it does not hold all the cards. The warm and toasty insulation brought by eco-friendly options isn’t to be discounted, displaying strong thermal performance. Aerogel insulation, specifically, boasts astounding insulating properties, despite its feather-light weight.

Environmental Impacts

Let’s dive into the environmental perspectives. Yes, bubble wrap insulation is recyclable, lightweight and requires reduced energy in its production. But it is not biodegradable and can stay in landfills for hundreds of years, challenging the eco-friendly label. Meanwhile, alternatives like cellulose make their mark. Made mostly from recycled newspaper, they champion biodegradability. Sheep’s wool and recycled denim also echo these sentiments, stepping up sustainability stakes.

Cost Effectiveness

Delving into the money matters, bubble wrap insulation shines with its affordability and cost-effectiveness, appealing to budget-conscious consumers. On the other side of the coin, you’ll find that eco-friendly insulation tends towards a higher price tag. But it’s an investment worthy of consideration for its long-term energy savings and reduced environmental footprint, painting a picture of true sustainability.

Future of Bubble Wrap and Sustainable Innovations

In the quest for sustainability, the industry of bubble wrap insulation transforms constantly, driven by technological innovation and an unyielding commitment to environmental preservation.

Technological Advances

Appreciating how technology plays a critical role in this arena, I’ll delve into the recent breakthroughs defining this evolution. A significant stride is the development of reusable bubble wrap. Made from durable polyethylene film, it can not only withstand multiple uses, but also decreases production demand and home energy usage. Another innovative approach revolves around the infusion of bubble wrap with eco-friendly insulation materials.

Inspiring instances include mixing bubble wrap with natural substances like plant-based fibers, enhancing biodegradability and reducing harm to ecosystems. Technological advances also extend to production, where energy-efficient methods decrease emissions and lower the insulation’s carbon footprint. Overall, these strides illustrate how cutting-edge technologies are driving the pathway towards a more sustainable future for bubble wrap insulation.

Evolution of Sustainable Packaging

In examining the evolution of sustainable packaging, I’ve noticed key trends. The use of recycled materials prominently stands out. Once-thrown-away bubble wrap now undergoes reconstitution, taking on a new life as cushioning or insulation in the packaging industry. This reduces the need for fresh resources and mitigates landfill overflow.

Packaging designs have also transformed, with sleek, minimalistic styles that use less material without compromising on protection. It’s interesting to see a circular economy in action, where waste becomes a resource and packaging life cycles are expanded. This signals a revolutionary shift in the packaging industry, setting the stage for a more resource-efficient, eco-friendly future. All these changes are fueled by a collective acknowledgement: sustainability isn’t optional; it’s necessary.

Leave a Reply