Hazardous spills pose a significant threat to the environment, often resulting in soil and water contamination that can have long-term impacts on ecosystems and public health. Typically, industrial activities, transportation accidents, and improper storage of chemicals can increase the risk of spills, making it crucial to have robust containment solutions in place.

Without proper management, the damage caused by hazardous materials can be devastating, which leads to the destruction of natural habitats, the loss of biodiversity, and even human health crises. Fortunately, there are several effective methods to prevent and mitigate the effects of hazardous spills.

Read on to learn more.

Understanding Hazardous Spills and Their Environmental Impact

A hazardous spill occurs when dangerous substances—such as chemicals, oil, or waste—are released into the environment. These substances can seep into the soil, rivers, oceans, or air, contaminating ecosystems and harming wildlife. The impact of a spill isn’t limited to the immediate area; pollutants can spread quickly, affecting large regions and even neighboring communities.

Furthermore, the consequences of these spills can be severe. Toxic chemicals can kill plants, fish, and other organisms, destabilizing ecosystems and disrupting the food chain. For humans, exposure to contaminated air or water can cause various health issues, from respiratory problems to long-term illnesses like cancer.

Spill Prevention: A Critical First Step

Preventing spills is the most effective way to protect the environment from hazardous materials. Industries and businesses that handle dangerous substances are responsible for implementing preventive measures to minimize the risk of accidental releases. Some key strategies for spill prevention include:

Proper Storage

Chemicals and other hazardous materials should be stored in containers durable, leak-proof, and resistant to corrosion. Regular inspections of storage units can help identify any potential weaknesses that could lead to leaks or spills.

Secondary Containment Systems

Secondary containment refers to additional barriers designed to prevent spilled materials from spreading beyond the primary storage unit.

One popular solution for this is the use of bunded pallets for the storage and transport of chemicals. These specially designed pallets feature built-in containment systems that can capture any leaks or spills to prevent them from reaching the ground or nearby water sources. By incorporating bunded pallets, businesses can significantly reduce the risk of environmental contamination.

Safety Training

Employees who work with hazardous substances must undergo comprehensive training to understand the risks involved and the protocols for safe handling. This training should be updated regularly to keep workers informed about the latest safety procedures.

Types of Spill Containment Solutions

When spills do occur, having the right containment solutions in place can prevent a minor incident from turning into an environmental disaster. Several methods have been developed to contain hazardous materials and mitigate the impact of spills. These include:

Spill Kits

Spill kits are essential tools that allow quick response to accidents involving hazardous substances. They typically include absorbent materials, personal protective equipment (PPE), and disposal bags to clean up and safely contain spills.

Spill kits are versatile and can be used for a range of hazardous materials, including chemicals, oils, and fuels. They should be strategically placed in areas where spills are most likely to occur, such as near storage facilities and loading docks.

Booms and Barriers

Booms are long, floating barriers used to contain spills in bodies of water. They’re particularly effective for oil spills, as they prevent the spread of the pollutant across the water’s surface. Booms come in various sizes and designs, depending on the type of material being contained and the condition of the water. When deployed early, booms can significantly reduce the damage caused by spills by isolating the affected area.

Drain Covers

Drain covers are used to block hazardous substances from entering drainage systems and contaminating water supplies. Made from durable materials like neoprene or rubber, these covers can create a seal over storm drains, ensuring that no pollutants can pass through. This solution is particularly useful in industrial settings where chemicals and oils are stored near drains.

Spill Berms

Spill berms are portable containment units designed to create a temporary barrier around spills. They’re commonly used in areas where hazardous liquids are transferred, such as loading docks or transfer stations. Berms can also be quickly deployed and are effective at containing large volumes of liquid. They’re often used in conjunction with absorbents to clean up spills efficiently.

Absorbents

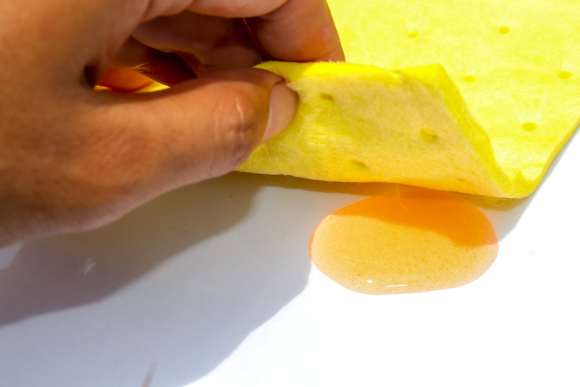

Absorbents are materials that can soak up hazardous substances, making them easier to contain and dispose of. These materials come in various forms, including pads, rolls, and granular substances. Absorbents are highly effective at minimizing the spread of spills, especially in the early stages of an accident. They’re often used alongside spill kits for quick response.

Regulatory Requirements for Spill Containment

In many countries, businesses that handle hazardous substances are required by law to have spill containment measures in place. These regulations vary depending on the location and the type of materials being stored or transported, but most focus on minimizing the environmental impact of spills.

For instance, the United States Environmental Protection Agency (EPA) has strict guidelines for spill prevention and containment. Under the Spill Prevention, Control, and Countermeasure (SPCC) rule, facilities that store large quantities of oil must develop and implement a spill prevention plan. This plan must include provisions for secondary containment, employee training, and emergency response procedures.

Similarly, in Australia, businesses are required to comply with the National Environment Protection (Assessment of Site Contamination) Measure (NEPM). This regulation sets out guidelines for managing contaminated sites and preventing further environmental damage.

Failure to comply with these regulations can result in significant fines and penalties, and reputational damage for businesses.

Long-Term Environmental Benefits of Spill Containment

Effective spill containment prevents immediate harm to the environment but also contributes to long-term sustainability. By minimizing the release of hazardous materials, businesses can protect natural resources, reduce the need for costly cleanup efforts, support biodiversity, and save the earth.

Containment solutions, such as bunded pallets, also promote a culture of environmental responsibility. Companies that invest in spill prevention and containment demonstrate their commitment to sustainable practices, which can improve their public image and foster stronger relationships with customers, investors, and regulatory agencies.

Moreover, by preventing spills, businesses can avoid the long-term costs associated with environmental remediation. Cleaning up contaminated sites is a complex and expensive process that can take years, if not decades, to complete. In contrast, investing in effective spill containment measures is a proactive approach that helps safeguard the environment and reduce operational risks.

Final Thoughts

Hazardous spill containment is a vital component of environmental protection, especially as industries continue to grow and expand. By keeping the information mentioned above in mind, businesses can protect nature from the devastating effects of hazardous spills, ensuring a healthier planet for future generations.

Leave a Reply