Solventless extraction is revolutionizing how industries produce essential oils, food products, and more. Unlike traditional methods that rely on harmful chemicals, this green technology harnesses natural processes to extract pure substances.

In the face of climate change and environmental decline, the world is increasingly in need of sustainable methods. Solventless extraction offers a cleaner alternative, promising significant reductions in energy use and carbon emissions.

In this post, we’ll explore the many ways in which solventless extraction is setting a new standard for environmentally responsible production.

Understanding Solventless Extraction

Solventless extraction involves techniques that separate desired compounds without using chemical solvents. Common methods include mechanical separation, as well as the application of heat and pressure, which are commonly used in rosin press operations.

These techniques are not only applicable to industrial processes but also have practical applications for garden plants, where extracting essential oils and other compounds can be done naturally and safely.

Compared to solvent-based methods, solventless extraction eliminates the risk of chemical residues, making the final products safer for both the environment and consumers. This natural approach aligns well with the increasing demand for sustainable and eco-friendly practices.

Environmental Benefits of Solventless Extraction

Solventless extraction offers a range of environmental benefits that make it a preferred choice for sustainable production. By avoiding chemical solvents, this method reduces pollution and energy consumption, ultimately lowering the overall carbon footprint of various industries.

No Chemical Solvents

Eliminating chemical solvents from the extraction process significantly reduces environmental hazards. Chemical solvents can leach into soil and water sources, causing long-term contamination and harm to ecosystems. By opting for solventless methods, industries prevent these pollutants from entering the environment, ensuring cleaner and safer production.

Furthermore, the absence of chemical solvents means there is no need for complex disposal methods. This reduction in hazardous waste management lowers operational costs and minimizes the risk of accidental spills and leaks. The result is a more streamlined and eco-friendly extraction process, especially when using a rosin press for a pure concentrate, which avoids the complications associated with chemical solvents.

Lower Energy Consumption

Solvent-based extraction methods require substantial energy, particularly for solvent recovery and purification. These processes involve heating, cooling, and pressurizing solvents, which consume significant amounts of energy. In contrast, solventless extraction techniques, like mechanical separation, are far less energy-intensive, leading to substantial energy savings.

The decrease in energy usage leads to reduced greenhouse gas emissions. Without the need for extensive heating or cooling, the carbon footprint of solventless extraction methods is considerably smaller.

Reduced Carbon Footprint

Reducing the emissions of greenhouse gases is crucial in the fight against climate change. Solventless extraction methods contribute to this goal by eliminating the energy-intensive processes associated with solvent recovery. This results in a notable reduction in carbon emissions from industrial activities.

Industries that adopt solventless extraction often report notable reductions in their overall carbon footprint. By using less energy and avoiding chemical solvents, industries can achieve more sustainable production practices, a principle that is also essential in sustainable gardening. This shift not only benefits the environment but also aligns with growing consumer demand for eco-friendly products.

The Most Common Types of Solventless Extraction

- Mechanical Separation: Involves physical methods like sieving or pressing to separate desired compounds from plant material. Examples include dry sifting and ice water extraction.

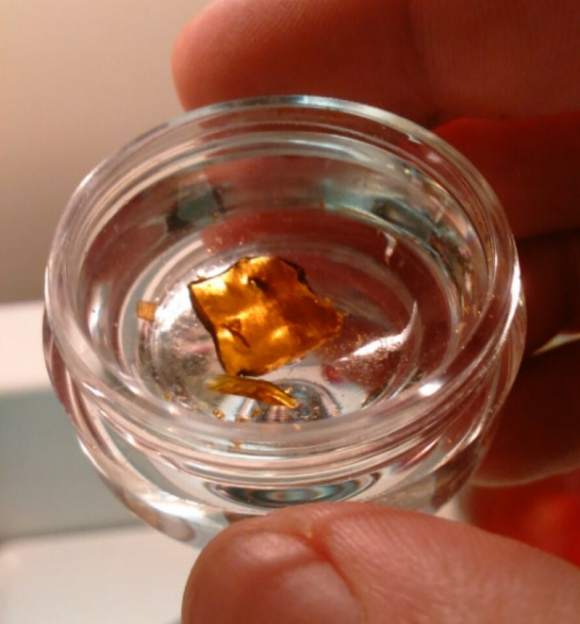

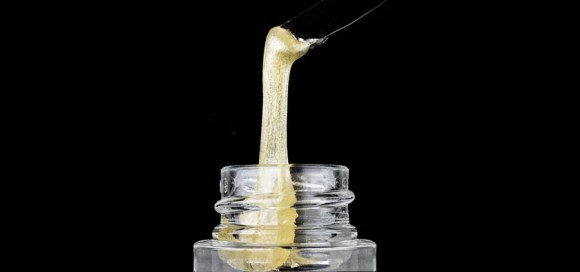

- Rosin Pressing: Uses heat and pressure to extract oils from plants. This method creates a pure and potent concentrate without the use of solvents.

- Cold Press Extraction: Often used in essential oil production, this method involves pressing plant materials at low temperatures to preserve delicate compounds.

- Steam Distillation: Utilizes steam to extract essential oils from plants, which condense back into liquid form.

Challenges and Considerations

While solventless extraction offers numerous benefits, it also presents certain challenges that industries must address. Understanding these challenges and considerations is crucial for successful implementation and scaling.

Technical Challenges in Scaling Up

Scaling up solventless extraction methods can be technically challenging. Methods like mechanical separation and rosin pressing may work well on a small scale but can be difficult to implement efficiently in large-scale operations. These processes often require precise control and consistency to maintain product quality.

Industries must invest in advanced equipment and training to overcome these challenges. Innovations in technology and process optimization can help address scalability issues. However, these advancements require time and resources, which can be a barrier for some companies.

Initial Investment Costs

Adopting solventless extraction methods can involve significant initial investment. Advanced equipment, such as industrial-scale rosin presses, can be expensive. Additionally, companies may need to invest in training for their workforce to effectively use and maintain the new technology.

Although the initial costs are substantial, the long-term savings and environmental benefits can outweigh these early expenses. Businesses need to carefully evaluate the cost-benefit ratio and consider the potential for future savings and sustainability improvements. Strategic planning and financial analysis are essential to make informed decisions about adopting solventless extraction.

Wrapping Up

Solventless extraction presents a sustainable and eco-friendly alternative to traditional extraction methods. Eliminating chemical solvents, reducing energy consumption, and lowering carbon footprints offer significant environmental, economic, and health benefits. Despite initial challenges, the long-term advantages make it a worthwhile investment for industries committed to sustainability. Transitioning to solvent-free extraction is crucial for a more sustainable and conscientious production future.

Leave a Reply